ECO-MAX

A true replacement of embodied carbon content

Eco-Cem is made locally, right here in New Zealand. Eco-Max is made with a mix of Eco-Cem and Xtra-Cem (GP) cement to create a superior concrete with 20-65 percent less carbon.

Key Benefits of Eco-Max

High Performance

Eco-Cem cement has a creamier finish and shrinks less, therefore produce better foundations, floors and precast panels.

Durability

Eco-Max is hard wearing with a denser finish meaning a longer design life and better chemical and stain resistance.

Low Shrinkage

Concrete made with Eco-Cem has a lower shrinkage performance.

Cost Competitive

Eco-Max is a cost competitive product with standard GP Cement.

Reduced Thermal Expansion

Eco-Cem is ideal for large concrete pours as it reduces the risk of thermal cracking.

Reduced Alkali Aggregate Reaction

Eco-Cem helps to minimise the risk of alkali-silica reaction in concrete.

Superior Finish

Pozzolanic cements have a creamier and denser finish which create an overall superior finish to your concrete projects.

Lower Embodied Carbon

The SCMs (Supplementary Cementitious Materials) substitutes the cement and creates 20-65% less embodied carbon.

Up to 65% replacement of GP cement

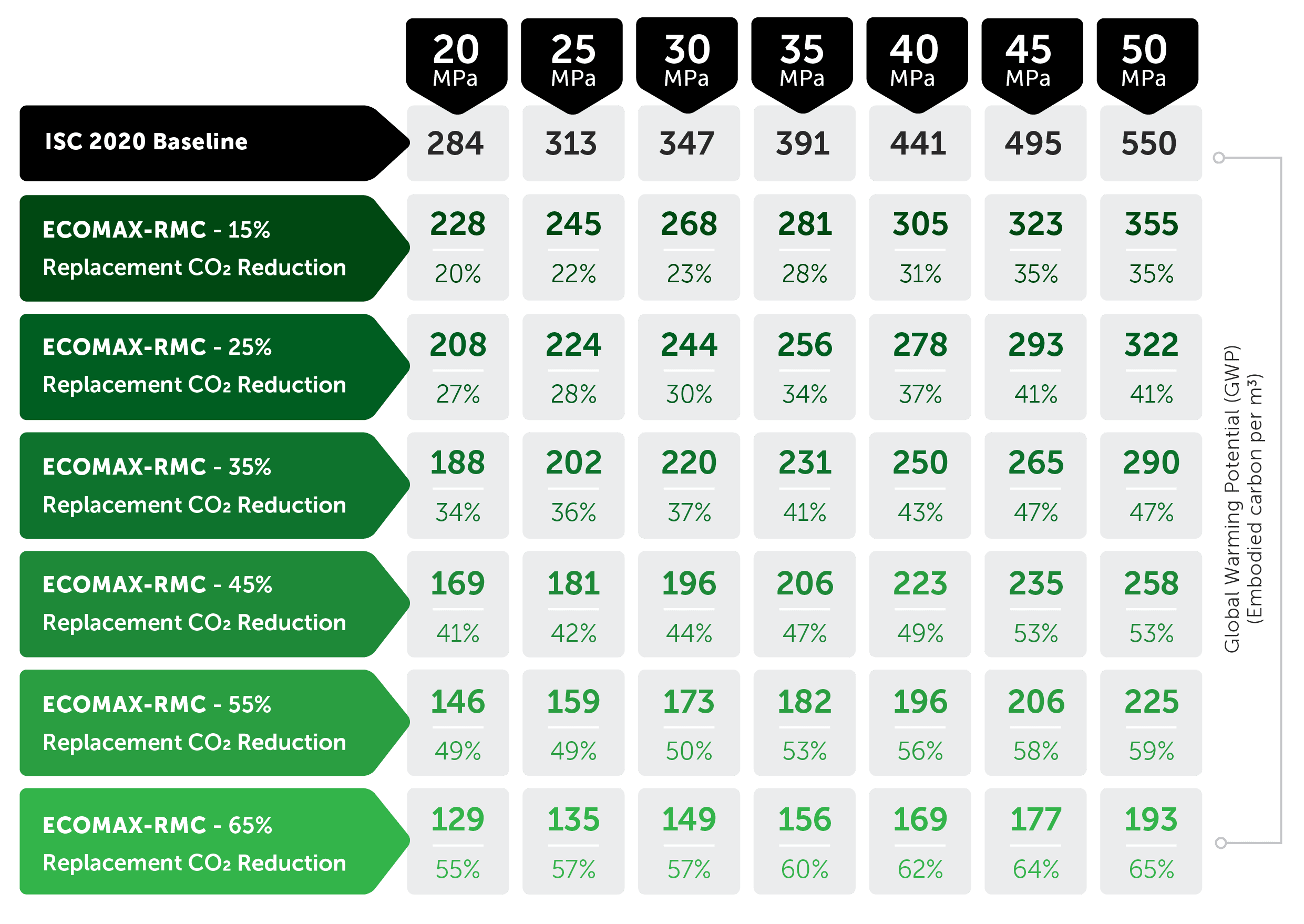

True GP Cement Replacement Eco-Max concrete can replace up to 65% of GP cement. GP cement contains 818kgs of embodied carbon per tonne, where Eco-Cem contains only 115kgs per tonne.

Embodied Carbon Reduction

We have developed the ratings in the graph below to give you an indication of our Embodied Carbon reductions across various products.

Meet your sustainable building goals with Ecomax RMC.

Find Us

35 Woodward St, Frankton,

Hamilton 3204